considered one of the most crucial elements used in construction is metal bars, which give support and reinforcement to concrete constructions.

high-quality assurance programs executed by manufacturers, which include ISO 9001, make sure constant quality all through the manufacturing system.

The difference between usual metal reinforcement bars and TMT bars is that they have quite a few strengths. allow us to check out them to know the indispensable job that corrosion-resistant TMT Bars play in building. We may even consider ways to determine the corrosion resistance of TMT bars.

For intricate models that require additional bending: QST bars, with their Extraordinary versatility, can be the winner.

TMT bars will also be devoid of torsional anxiety since they aren’t place by way of any Bodily deformations. consequently, probabilities of floor defects are Just about zero. Reduction in area defects signifies that TMT bars are less vulnerable to unsafe oxidation, like corrosion, compared to TOR metal.

Improved energy: The swift cooling through quenching creates a hardened outer layer, offering the TMT bars with significant tensile energy. the next self-tempering approach converts the martensite into tempered martensite, imparting additional strength and toughness.

in comparison to HYSD bars TMT bars have higher anxiety-bearing limitations because of their exceptional processing the bars have a hard outer floor in addition to a softer Main. This not just withstands high anxiety and also delivers smoother weldability.

This assists in assessing the corrosion resistance of explained TMT bar. Usually, this technique is coupled with other tactics to perform elaborate checks and attain a comprehensive knowledge of the corrosion mechanisms influencing the TMT steel bars.

RUST RESISTANT: Failure in almost any reinforcement concrete transpires as a result of corrosion. TOR steel corrodes within the concrete as a result of its high focus of chloride ions.

Through this blog, we will assist you to in dissecting the importance of TMT bar grades. in this article, We'll explore their mechanical Qualities along with the effects of different grades on structural integrity.

TMT bars of increased grades, specifically Fe550 and Fe600, show Increased ductility and toughness, important in seismic zones. they supply improved resistance to your lateral forces expert in the course of earthquakes, reducing the risk of structural failure.

The Rama group was proven in 12 months 1973 and it has carved out a outstanding put amongst buyers during.

D range TMT bars are produced as a result of special category of billets and critically controlled thermal therapy during producing procedure. The best part of D wide range TMT bars are they are The perfect product or service for earthquake resistance and thoroughly free of mechanical fatigue .

In summary, knowing TMT bar grades and field benchmarks is elementary for the two design specialists and property entrepreneurs. It ensures that the components used in a construction task are of the highest good quality, contributing to the security and longevity of your construction.

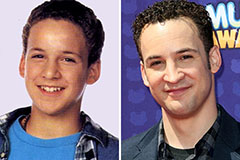

Ben Savage Then & Now!

Ben Savage Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now!